Vincent Dassi, a graduate of the Design Academy Eindhoven, has developed a form of paper mache that anyone can use to make and repair household items from recycled cardboard.

Zellstoff Dassi uses a food processor to turn cardboard into paper pulp, which he then shapes into 3D shapes using various techniques.

The material can be used to create new objects, repair broken or disused objects, or adapt objects for different purposes.

Dassi used cardboard to fix various items, including a vacuum cleaner

“As a designer, you can feel very stressed and guilty when you create objects,” says Dassi, who studied in the DAE’s Bachelor’s degree.

“I wanted to find a way to create properties with the lowest possible environmental cost,” he told Dezeen.

The designers post tutorials online to encourage others to follow suit

The designers post tutorials online to encourage others to follow suit

The project is deliberately low tech as he wanted to create an approach that would be easy for others to replicate.

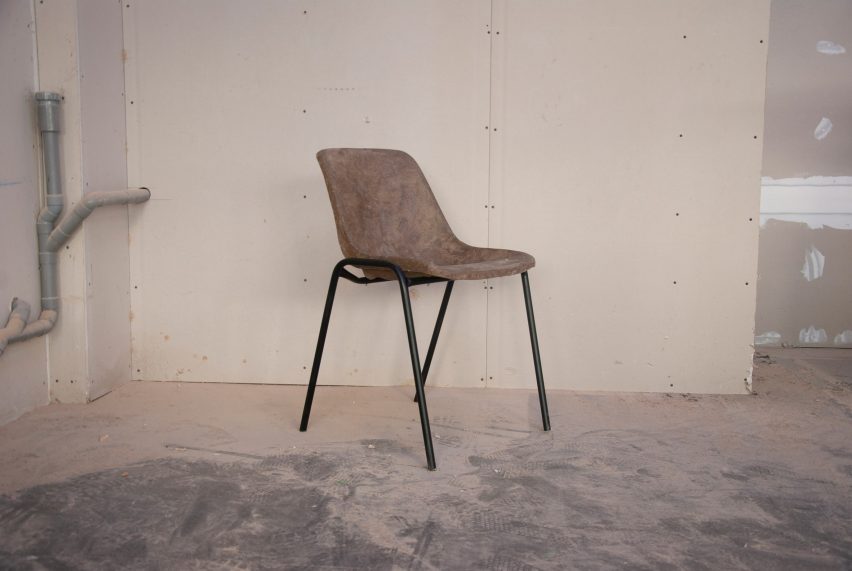

He published the “recipe” for his paper pulp on the Pulp It website, where he also shows videos showing how to make everyday objects such as a chair and a desk lamp.

Objects Dassi made include a laundry bin, dustpan and brush

Objects Dassi made include a laundry bin, dustpan and brush

The designer said his goal is to provide an alternative to consumer culture by allowing people to handcraft their own objects from local materials rather than buying them online.

“The manufacturer is no longer a simple consumer, but participates in the manufacturing process, which leads to a better appropriation of the object,” he said.

The designer also used cardboard to fix a broken guitar

The designer also used cardboard to fix a broken guitar

Dassi’s paper pulp recipe consists of two ingredients, both of which are made in a blender.

The first is paper clay, which is made from shredded paper mixed with water. The second is a glue made by combining rice flour with boiling water.

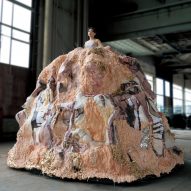

The huge dress by Hsin Min Chan strengthens its wearer by making her aloof

The designer also built his own press, which he uses to squeeze the water out of his paper clay.

Instructions for building with simple standard materials can be downloaded from the website.

A broken chair was mended with a new seat

A broken chair was mended with a new seat

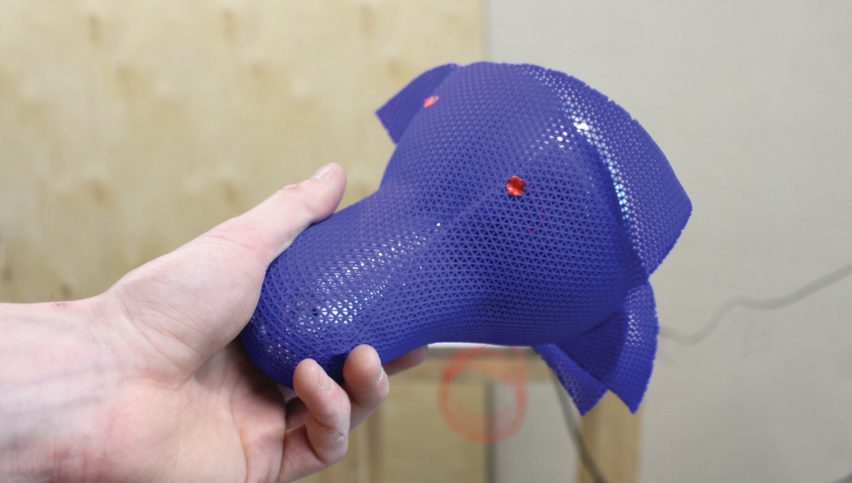

To shape the cardboard mass, Dassi developed a simple method that involves 3D printing a mesh of PLA plastic and then heating it so it can be molded around a surface. Then he fixes the formwork with a 3D pen.

Once the shape is formed, it can be used as a mold to help set the pulp inside.

“This project is about being autonomous and local,” explained Dassi. “You can make this material yourself and it can accommodate any need.”

Dassi has developed a paper press that can be built from simple materials

Dassi has developed a paper press that can be built from simple materials

The tied pulp should keep its shape, even though it is not waterproof. Dassi suggests adding a wax coating, but notes that doing so will make it difficult to recycle the material.

“The fact that it is water sensitive can be seen as an advantage,” he suggested, noting that the waterproof properties of plastic lead to waste and pollution.

Sheets of 3D printed PLA are used as molds for the pulp

Sheets of 3D printed PLA are used as molds for the pulp

The project was exhibited at the DAE graduate exhibition, where other projects on display were garments for healing trauma, a giant dress, and tools to turn human breath into clouds.

The DAE Graduation Show 2021 was exhibited from October 16 to 24 as part of the Dutch Design Week. Check out the Dezeen Events Guide for an up-to-date list of architecture and design events taking place around the world.