January 5, 2022

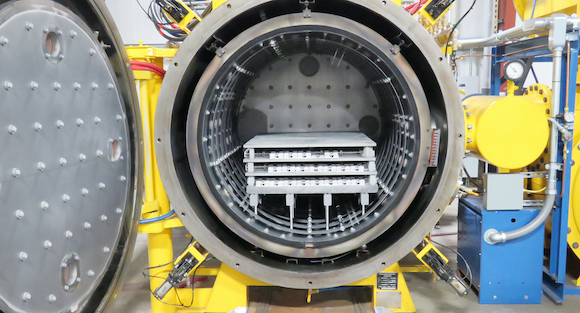

The projected maintenance costs on the retrofitted vacuum furnace are 94% less than the labour and material costs of maintaining a traditional vacuum furnace (Courtesy Solar Atmospheres of Western PA)

After a month’s production, the new retrofitted vacuum furnace from Solar Atmospheres of Western PA, Hermitage, Pennsylvania, USA, is reported to perform with positive results. Originally announced in 2021, the furnace is intended for use in a new Metal Injection Moulding (MIM) and sinter-based Additive Manufacturing applications.

After repeated 1,316ºC sintering cycles, the hot zone is said to have remained immaculately clean, with the problematic binders coalescing exactly where they were targeted to consolidate: within a separate heated pumping port, thus keeping the primary pump and booster uncontaminated. The customer utilising the furnace also reported that its sintered parts processed in this new furnace ‘never looked better’ and met critical density and dimensional requirements.

The company anticipates that maintenance savings on this dedicated furnace versus processing in a traditional vacuum furnace will be considerable; processing this job in a conventional vacuum furnace required a scheduled monthly shutdown. Solar’s maintenance team had to extract the hot zone; replace the ceramics; clean or replace the power feed through terminals; scrape the cold walls; clean the diffusion pumps; and scour all the pumping system pipes. The added labour and material costs coupled with the lost production time and degradation on the life of the hot zone cost the company more than $180,000 per year. The projected maintenance costs on this newly designed sintering furnace will be $10,000 per year.

“Knowing the effects of what MIM and certain AM processing had done to our equipment in the past, Bill Jones and the engineers at Solar Manufacturing developed an innovative solution for us,” stated Bob Hill, president of Solar Atmospheres of Western PA. “Having this newly designed vacuum furnace will be an asset for our future in MIM and AM processing.”

www.solaratm.com

Recent News

-

January 10, 2022

Jiangxi Yuean Advanced Materials Co Ltd, Ganzhou City, China, has begun construction of a new Carbonyl Iron Powder (CIP) production line. The new C…»

-

December 27, 2021

On-demand digital manufacturing service provider Fathom Digital Manufacturing Corp, Hartland, Wisconsin, USA, began trading on the New York Stock E…»

-

December 14, 2021

ASTM International’s Additive Manufacturing technologies committee (F42) has approved a new standard guide for the use of layer-based Material Ex…»

-

January 6, 2022

Nichols Portland, Inc, headquartered in Portland, Maine, USA, has acquired the assets of Alpha Precision Group, LLC (APG), St Mary’s, Pennsylvani…»