To ensure that facilities run smoothly and reduce overall maintenance costs without undue revenue loss because of downtime, an efficient furnace lining is crucial. The five tips below should be considered to keep a furnace lining running efficiently.

Image Credit: Morgan Advanced Materials – Thermal Ceramics

Tip 1 – Evaluate the Furnace Liner by Using Infrared (IR) Thermography Inspection

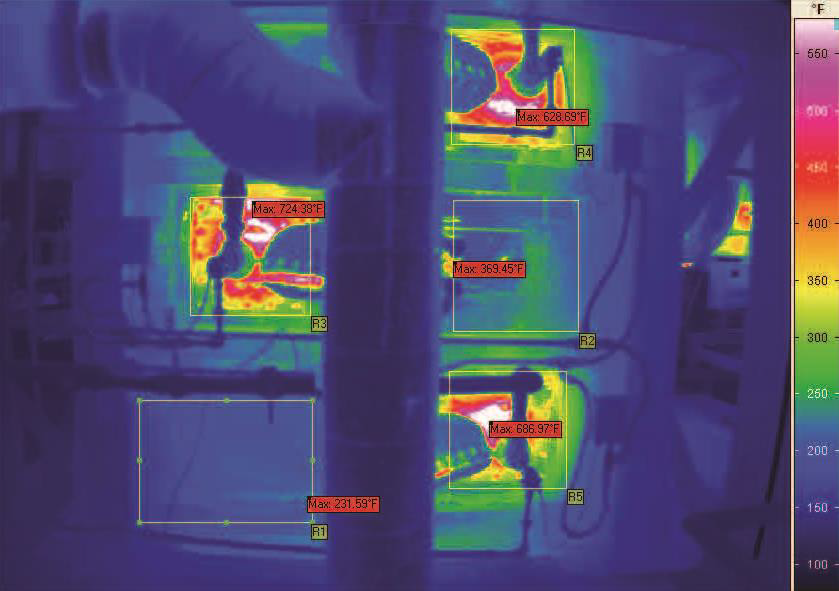

To assess the quality of the furnace lining, Infrared (IR) thermography scans are a vital step. Lining quality is crucial for protecting the steel from heat, promoting overall furnace efficiency and limiting heat loss.

Usually, the scan involves pointing an IR camera at numerous points on the furnace casing to analyze the outside temperature and identify hot spots where the unit is leaking heat or experiencing design issues that might not be visible from the outside. With a painted surface, this is a problem.

Obviously, scanning from the outside is a huge advantage as the unit can still operate. An IR camera detecting hot spots or other problems with the lining is shown in Figure 1.

In many instances, specially trained applications engineers carry out infrared imaging, analyze the IR scans and give recommendations on the most appropriate repair choices.

Figure 1. Infrared (IR) Scan showing hot spots. Image Credit: Morgan Advanced Materials – Thermal Ceramics

Tip 2 – Use Online Maintenance Repair

Online repairs should be conducted wherever possible depending upon the difficulty of getting to an area, the temperature or how big the hot spot is. Most maintenance managers prefer the online repair option as it is fast, reliable and economical.

Boilers and process units are producing revenue, so it is extremely valuable if repairs can be performed while the unit is online. This avoids revenue loss from the unit in question, in addition to the consequential losses from shutting down additional connected units.

For instance, where IR scans show that online repairs are recommended, Morgan Technical Ceramics Limited’s Thermal Ceramics pumpable Superwool® or Kaowool® can be pumped from the outside of the furnace or boiler, filling cracks and voids due to deteriorated insulation.

These products are perfect for supplying enhanced thermal insulation efficiencies behind boiler tubes in seals, sidewalls and floors, in addition to repairs of ovens, furnaces and process equipment.

When performing traditional repairs, the furnace has to be shut down and cooled until it is safe for maintenance personnel to enter and repair the lining with pumpables, fiber blankets or monolithics.

Figure 2. Installing Pumpable into the hot spot while furnace remains online. Image Credit: Morgan Advanced Materials – Thermal Ceramics

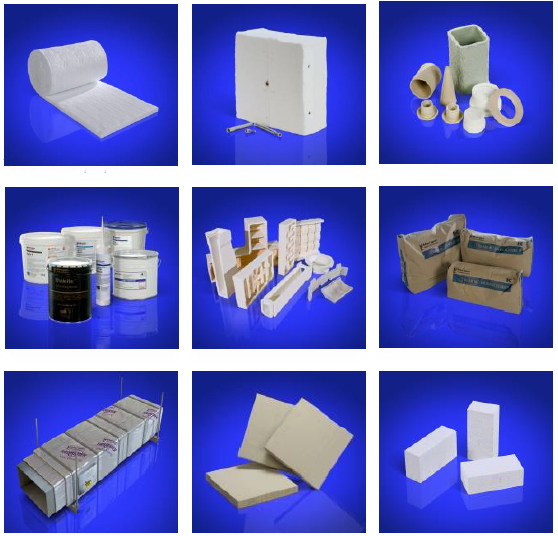

Tip 3 – Choose the Right Material for Furnace Rebuilds

The unit must be shut down for a furnace reline or process heater reline if IR scans show that the area of concern is too large for online repairs. Material choice is crucial to a successful furnace rebuild which will enhance reliability and efficiency and lower maintenance costs.

Material properties may vary depending upon the furnace’s application, these include mechanical resistance, hardness, density or the insulating factor. Choosing the proper material is often performed by utilizing a heat flow analysis software program in which temperature and use factors are inputted to gather information on the best material of choice.

It is worth considering that numerous units have old-style insulation; as there are so many new, more efficient insulation varieties now on the market, upgrading when you have to reline the furnace should be considered.

For instance, Morgan Technical Ceramics Limited’s Thermal Ceramics Superwool® Plusfibre has up to 20 percent less thermal conductivity than competitive insulations. As a result Superwool Plusfibre is 17 percent more energy efficient than traditional Refractory Ceramic Fibre (RCF) and any other Alkaline Earth Silicate (AES) insulations.

A breakthrough in the company’s advanced manufacturing control has enabled the product to be engineered to maximize the fiber content. For those looking to move away from RCF insulation, its low biopersistence also makes it a good replacement.

Figure 3. Variety of materials used in furnace rebuilds and process equipment. Image Credit: Morgan Advanced Materials – Thermal Ceramics

Tip 4 – Carefully Consider Engineering Design

After choosing the right materials, it is important to ensure that the engineering design is suitable. Engineering is extremely vital to make sure that the furnace relining is as long-lasting as possible.

Ensure that the materials have enough studs to hold them in place and have sufficient joints for shrinkage or expansion. For example, the brick could grow if you install a brick lining without the proper expansion joints and end up pushing the entire lining off the furnace wall.

Tip 5 – Proper Installation is Key to Success

Ensure that the installation of furnace lining material is performed correctly and those carrying out the job have the right skills for the job. There is a large range of products available and each one has different installation needs.

For instance, if the concrete is not mixed with the right amount of water at the proper temperature for concrete products, the material will not develop. It will be difficult to place and will not reach expected properties. Put simply, if it is not installed correctly, it is as bad as not having a good design and not making a good material choice.

Acknowledgments

This information has been sourced, reviewed and adapted from materials provided by Morgan Advanced Materials – Thermal Ceramics.

For more information on this source please visit Morgan Advanced Materials – Thermal Ceramics.